News

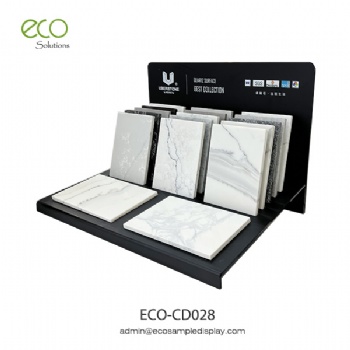

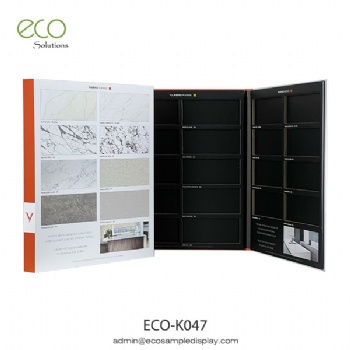

how to print logo on the stone display rack

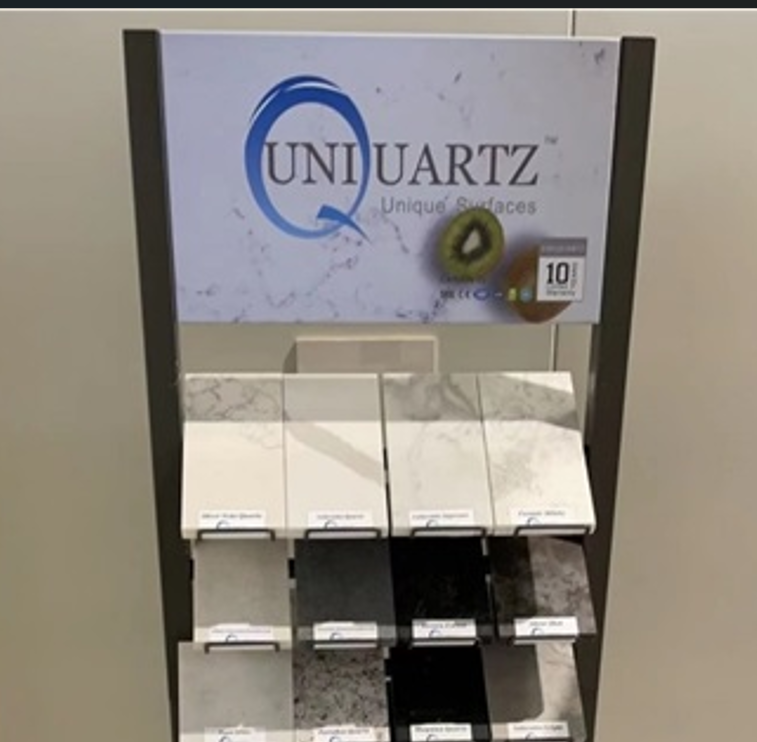

Silk screen printing is know as screen printing, under the pressure of the mesh brush, the ink passes through the screen. The stone display rack is printed with the same pattern as the screen. Silk screen printing has become the most common process due to its simple and fast operation.

Silk screen printing requires plate making, ink blending (ink blending requires experience) according to pantone color number, artificial can only

reach close. And in addition to using colors such as "white and black", others require Pantone color numbers.

Metal , wood pr acrylic products in the screen printing, if your logo is a color, you only need to make a plate;

if logo colors more than two more color pattern printing, the corresponding screen fee, labor costs are not cheap. Therefore, when there are

many colors and gradient colors, silk screen printing has no advantage. You need to choose according to the actual situation.

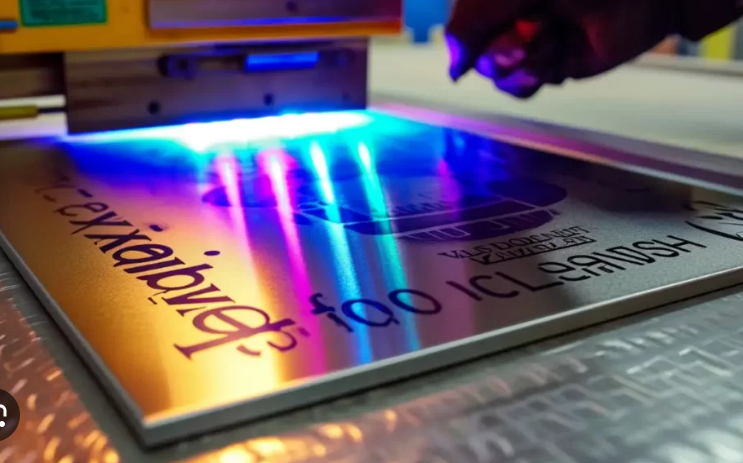

UV printing is know as UV digital printing, which is one of the most flexible and exciting direct-to-object print processes ever created,

and its uses are almost limitless. This costs is much higher than silk screening.

UV printing is a unique method of digital printing utilising ultraviolet (UV) light to dry or cure ink, adhesives or coatings almost as soon as

it’s hit the paper, or aluminium, foam board or acrylic

The benefits of UV printing include:

fast production with instant ink curing

the capability to print directly on a wide range of materials

and the ability to print 3D textures, effects and gloss highlights.

Using UV printing technology, you can print custom designs, images, text and even textures directly onto a vast range of materials or products.

![]()

Categories

Contact Us

- +86-13459205507

- +86-13459205507

- Ashley@ecosampledisplay.com

- Skype

- +86-18259404245